Spray cans are a staple in our daily lives, offering a convenient and efficient way to apply a variety of substances, from paint and insecticides to deodorants and cooking oils. At the heart of every spray can is a small but mighty component—the valve mechanism. This mechanism is the unsung hero that transforms liquid into a fine mist, allowing for even and controlled application. Imagine a world without the ease of spray cans; we’d be stuck with messy brushes or inefficient pouring methods. The valve mechanism is what makes spray cans a preferred choice for many, providing precision and control that are unmatched by other application methods.

Why does this matter to you? Whether you’re an artist looking to create intricate graffiti, a homeowner tackling a DIY project, or simply someone who enjoys the convenience of spray deodorant, understanding how spray can valves work can enhance your experience and ensure you get the most out of your product. Knowing how these mechanisms operate can help you troubleshoot issues, extend the life of your spray cans, and choose the right product for your needs.

What is a Spray Can Valve Mechanism, and Why Does It Matter to You?

The Silent Hero of Everyday Convenience

The spray can valve mechanism is a small yet crucial component that plays a big role in the functionality of spray cans. This mechanism controls the release of the can’s contents, allowing for a fine mist to be sprayed evenly across a target surface. Without it, the contents would either remain trapped inside or gush out uncontrollably.

How It Impacts Your Daily Life

Think about the last time you used a spray can. Was it to paint a wall, apply deodorant, or perhaps clean a surface? The valve mechanism was working behind the scenes to ensure that you could apply the product smoothly and evenly. Understanding how these mechanisms operate can help you make informed choices about the products you use and troubleshoot any issues that may arise.

The Most Common Reasons People Turn to Spray Can Valves

From Artistry to Maintenance: Everyday Uses

Spray can valves are indispensable in various fields. Artists rely on them for their ability to deliver paint with precision and ease. Homeowners use them for quick fixes and maintenance tasks, such as painting fences or applying insect repellent. The versatility of spray cans makes them a popular choice for a multitude of applications.

The Appeal of Efficiency and Precision

Spray cans offer a level of efficiency and precision that is hard to beat. The valve mechanism allows for controlled release, ensuring that just the right amount of product is dispensed. This not only prevents waste but also ensures a neat and tidy application, making spray cans a go-to solution for many.

The Backstory or Essentials Behind Spray Can Valve Mechanisms

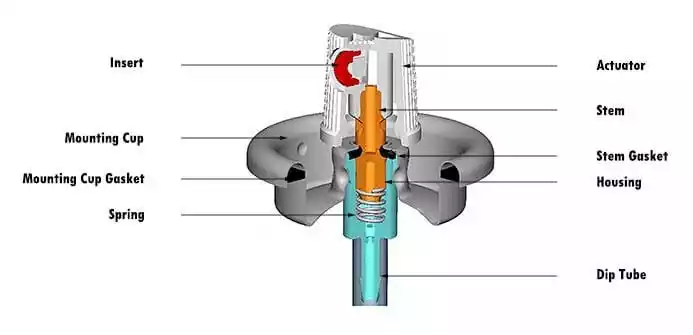

Spray can valve mechanisms are a marvel of engineering, designed to withstand the pressure inside the can while providing a reliable and consistent spray. The basic components include the nozzle, the valve stem, the spring, and the gasket. Each part plays a vital role in the overall functionality of the mechanism, working together to deliver a fine mist or stream.

Where It All Began: A Brief History or Origin Story

The Evolution of Aerosol Technology

The concept of aerosol technology dates back to the late 18th century when self-pressurized spray devices were first conceived. However, it wasn’t until the mid-20th century that modern spray can technology took shape. The first aerosol spray can was patented in 1927, but it gained widespread use during World War II when it was used to distribute insecticides to troops in the Pacific. This innovation paved the way for the diverse range of spray products we have today.

Key Innovations That Changed the Game

Over the years, several key innovations have shaped the development of spray can valve mechanisms. The introduction of the continuous spray valve in the 1940s allowed for a more consistent and reliable spray. This was followed by the development of environmentally friendly propellants and ergonomic designs that improved user experience.

How It’s Evolved Over Time or Why It’s Relevant Today

Modern Improvements and Their Impacts

Today’s spray can valve mechanisms have evolved to offer improved performance and sustainability. Manufacturers have introduced valves that can handle thicker, more viscous products, expanding the range of potential applications. Additionally, advances in materials and design have led to more durable and reliable valve mechanisms.

The Shift Towards Eco-Friendly Alternatives

In recent years, there has been a significant shift towards eco-friendly alternatives in the aerosol industry. Many manufacturers have adopted environmentally friendly propellants, such as compressed air or natural gases, to reduce the environmental impact of spray cans. This shift not only helps protect the planet but also appeals to environmentally conscious consumers.

Common Issues or Key Points to Know

Spray can valves, like any other mechanical component, can encounter issues over time. Understanding these common problems can help you maintain the functionality of your spray cans and extend their lifespan.

What You’ll Notice First About Spray Can Problems

Signs Your Spray Can Isn’t Working Right

When a spray can isn’t working as it should, you’ll likely notice a few tell-tale signs. The spray may become inconsistent, sputtering instead of delivering a smooth mist. This is often a sign of a clogged nozzle or a problem with the valve mechanism itself.

The Tell-Tale Sputter: What It Means

A sputtering spray can be frustrating and is usually caused by a blockage in the nozzle or a malfunction in the valve. This can occur due to a build-up of dried product or debris, preventing the smooth flow of the contents. Understanding how to address this issue can save you time and prevent waste.

The Most Common Questions or Concerns People Have

Why Won’t My Spray Can Spray?

When a spray can refuses to spray, it can be due to several reasons. A clogged nozzle is a common culprit, often caused by residual product drying in the nozzle opening. To fix this, try soaking the nozzle in warm water or cleaning it with a pin. If the problem persists, it may be an issue with the valve mechanism, such as a misaligned or damaged component.

Is It Safe to Use an Old Can?

Using an old spray can can be safe if the can has been stored properly and shows no signs of damage or rust. However, it’s essential to check the expiration date and shake the can before use to ensure the contents are still viable. If you notice any unusual sounds or smells, or if the spray is inconsistent, it’s best to discard the can safely.

Table: Breaking Down the Key Features or Issues at a Glance

| Feature | Common Issues |

|---|---|

| Nozzle Design | Clogging |

| Valve Pressure | Inconsistent Spray |

Let’s Break It Down: Understanding the Components

The spray can valve mechanism is composed of several key components, each contributing to its overall function. By understanding these components, you can gain a deeper appreciation for how spray cans work and troubleshoot any issues that arise.

Inside the Mechanism: How It All Fits Together

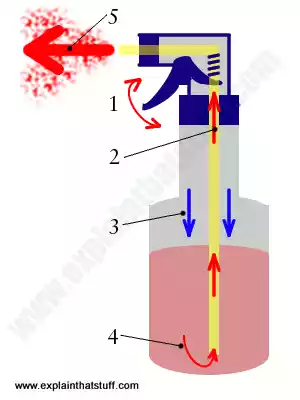

The valve mechanism is a complex interplay of parts designed to handle the high pressure inside the can while providing a smooth and consistent spray. The nozzle controls the pattern and pressure of the spray, while the valve stem and spring work together to regulate the flow of the contents. The gasket ensures a tight seal, preventing leaks and maintaining pressure.

The Science of Pressure and Release

At the core of every spray can valve mechanism is the science of pressure and release. The can is filled with both product and propellant, which creates pressure inside the can. When the nozzle is pressed, the valve opens, allowing the pressure to force the product out as a fine mist. Understanding this process can help you troubleshoot issues and optimize your spray can use.

Personalized Guidance on This Step

Choosing the Right Spray Can for Your Needs

When selecting a spray can, consider the type of product you need and the specific application. For example, spray paints come in a variety of finishes and colors, while insecticides may offer different active ingredients. Consider the nozzle design and the type of spray pattern it produces to ensure it meets your needs.

Maintenance Tips for Longevity

To prolong the life of your spray cans, store them in a cool, dry place away from direct sunlight. Clean the nozzle after each use to prevent clogs, and give the can a good shake before each application to ensure the contents are well-mixed. Following these simple steps can help you get the most out of your spray cans.

Real-Life Examples or Practical Applications

How Spray Can Valves Work in the Real World

Spray can valves are used in a variety of real-world applications, from household tasks to artistic endeavors. Understanding how they work can enhance your experience and ensure you get the most out of your product.

Everyday Scenarios Made Easier

Spray cans make everyday tasks easier, whether you’re painting a room, applying sunscreen, or cleaning a surface. The convenience and efficiency of spray cans make them a popular choice for many tasks, saving you time and effort.

The Art of Spray Painting: Tips from Pros

For artists, spray painting is a unique and versatile medium that allows for creativity and expression. Professional spray painters recommend starting with a clean surface and using smooth, even strokes to achieve the desired effect. Experimenting with different nozzle settings and spray patterns can help you achieve a variety of textures and finishes.

Here’s What Happened When [Person/Expert/Customer] Used It

A Painter’s Perspective: Mastering the Spray

Professional painters often rely on spray cans for their ability to deliver even and consistent coverage. One painter shared that mastering the spray technique involves understanding the distance and angle of the nozzle relative to the surface. This allows for precise control over the application, resulting in a flawless finish.

DIY Enthusiasts Share Their Success Stories

DIY enthusiasts often turn to spray cans for their convenience and ease of use. One customer shared their success story of using a spray can to repaint an old piece of furniture, transforming it into a modern statement piece. They emphasized the importance of preparation, including cleaning and priming the surface, to achieve the best results.

Table: Comparing Real-World Applications or Outcomes

| Application | Outcome |

|---|---|

| Graffiti Art | Precision and Control |

| Home Maintenance | Quick and Efficient |

Common Fixes or Things You Can Do

Here’s How You Can Solve It

Spray can issues can often be solved with simple fixes. Understanding the common problems and their solutions can save you time and frustration.

Quick Fixes for Common Problems

• Clogged Nozzle: Remove the nozzle and soak it in warm water to dissolve any dried product. Use a pin to clear any remaining debris.

• Inconsistent Spray: Shake the can vigorously to ensure the contents are well-mixed and check for any blockages in the nozzle or valve.

When to Call in the Experts

If you’ve tried the above fixes and your spray can still isn’t working, it may be time to consult a professional. They can help diagnose and resolve more complex issues, such as a malfunctioning valve mechanism or damaged components.

Easy Fixes You Can Try First, Without Needing an Expert

Unclogging Your Nozzle at Home

Clogged nozzles are a common issue and can often be resolved with a little DIY effort. Start by removing the nozzle and soaking it in warm water to dissolve any dried product. If the blockage persists, use a pin to gently clear the opening. This simple fix can restore your spray can to full functionality.

Adjusting Pressure for Better Results

Inconsistent spray can often be attributed to insufficient pressure inside the can. To address this, ensure the can is shaken well before use to mix the contents. If the problem persists, check the valve mechanism for any signs of damage or misalignment. Adjusting these components can help restore consistent spray performance.

What Experts Say: Quotes and Insights

Understanding your tools is key to mastering your craft. A professional painter shared that getting to know the ins and outs of spray can valve mechanisms can enhance your painting experience and ensure you achieve the best results. They emphasized the importance of preparation, including cleaning and priming surfaces, to achieve a flawless finish.

When Things Don’t Go as Expected

How to Spot When Something Isn’t Right

Recognizing the signs of a malfunctioning spray can is crucial to addressing issues promptly. If you notice inconsistent spray, sputtering, or a complete lack of spray, it’s time to investigate further. These signs can indicate a clogged nozzle, insufficient pressure, or a malfunctioning valve mechanism.

Troubleshooting On the Go

When you’re in the middle of a project and encounter spray can issues, quick troubleshooting can save the day. Start by checking the nozzle for blockages and ensure the can is properly shaken. If the problem persists, inspect the valve mechanism for any signs of damage or misalignment.

Common Mistakes to Avoid

Overuse and Misuse: What Not to Do

Using spray cans incorrectly can lead to a host of issues. Avoid overusing the product, as this can lead to clogs and inconsistent spray. Misuse, such as spraying too close to the surface, can result in drips and uneven application. Understanding the proper technique can help you avoid these common pitfalls.

Avoiding Damage with Proper Storage

Proper storage is key to maintaining the functionality of your spray cans. Store them in a cool, dry place away from direct sunlight and extreme temperatures. This helps preserve the contents and prevent damage to the valve mechanism.

Table: Problem-Solution Mapping

| Problem | Solution |

|---|---|

| Clogged Nozzle | Clean with Solvent |

| Inconsistent Spray | Check Valve Pressure |

Your Best Options or Alternatives

If Spray Can Valves Aren’t for You, Here’s What to Consider Instead

While spray cans offer convenience and precision, they may not be the best choice for every application. Exploring alternatives can help you find the right tool for your needs.

Exploring Pump Sprayers and Their Benefits

Pump sprayers offer a reusable and eco-friendly alternative to spray cans. They allow for greater control over the spray pattern and pressure, making them ideal for certain applications. However, they may lack the precision and convenience of spray cans, so consider your specific needs before making a decision.

Understanding the Pros and Cons of Alternatives

When considering alternatives to spray cans, weigh the pros and cons carefully. Pump sprayers, for example, offer environmental benefits and reusability, but may require more effort to operate and lack the precision of spray cans.

Table: Comparison of Alternatives or Substitutes

| Option | Pros | Cons |

|---|---|---|

| Pump Sprayer | Reusable, Eco-Friendly | Less Precision |

FAQ Section

How Can I Make Sure My Spray Can Lasts Longer?

To extend the life of your spray can, proper storage and maintenance are key. Store the can in a cool, dry place away from direct sunlight, as extreme temperatures can affect the pressure and integrity of the can. After each use, clean the nozzle to prevent clogs and ensure smooth spray performance. Shaking the can before each use helps mix the contents and maintain consistent pressure. Regularly check the expiration date and replace old cans to ensure optimal performance. By following these simple steps, you can prolong the life of your spray can and get the most out of your product.

What Should I Do If My Nozzle Is Stuck?

A stuck nozzle can be a frustrating issue, but it’s often easy to resolve. Start by removing the nozzle and soaking it in warm water to dissolve any dried product. If the blockage persists, use a pin to gently clear the opening. Reattach the nozzle and test the spray. If it remains stuck, check the valve mechanism for any signs of damage or misalignment. In some cases, replacing the nozzle with a new one may be necessary. By taking these steps, you can restore your spray can to full functionality and avoid unnecessary waste.

Is It Safe to Use an Old Spray Can?

Using an old spray can is generally safe if the can has been stored properly and shows no signs of damage or rust. However, it’s important to check the expiration date and shake the can before use to ensure the contents are still viable. If you notice any unusual sounds or smells, or if the spray is inconsistent, it’s best to discard the can safely. Old cans may also have compromised valve mechanisms, leading to leaks or reduced spray performance. By following these guidelines, you can use old spray cans safely and effectively.

Why Is My Spray Can Sputtering?

A sputtering spray can is often caused by a clogged nozzle or a malfunctioning valve mechanism. To address this issue, remove the nozzle and clean it with warm water or a solvent to dissolve any dried product. If the problem persists, check the valve mechanism for any signs of damage or misalignment. Shaking the can vigorously can also help mix the contents and restore consistent spray performance. By understanding the causes of sputtering and taking the appropriate steps, you can resolve the issue and ensure smooth and even application.

Can I Use a Spray Can for Thick Products?

Spray cans are typically designed for thin, liquid products, but some are specifically formulated for thicker substances. When using a spray can for thick products, check the label to ensure it’s suitable for the intended use. If the product is too thick, it may clog the nozzle or cause inconsistent spray. In some cases, thinning the product with a compatible solvent can help achieve better results. By selecting the right spray can and following these guidelines, you can use spray cans for thick products effectively.

How Can I Avoid Clogs in My Spray Can?

Clogs are a common issue with spray cans, but they can be prevented with proper maintenance. After each use, clean the nozzle to remove any residual product that may dry and cause blockages. Store the can in a cool, dry place to prevent the contents from thickening. Shaking the can before each use ensures the contents are well-mixed and reduces the risk of clogs. By following these simple steps, you can avoid clogs and ensure smooth spray performance.

What Are the Benefits of Using Spray Cans?

Spray cans offer numerous benefits, including convenience, precision, and efficiency. They allow for even and controlled application, reducing waste and mess. Spray cans are also versatile, suitable for a wide range of applications, from painting and maintenance to personal care and cleaning. Their portability and ease of use make them a popular choice for both professionals and DIY enthusiasts. By understanding the advantages of spray cans, you can make informed decisions about their use and get the most out of this convenient tool.

How Long Will It Take to Get This Done?

Addressing spray can issues can often be done quickly with simple fixes. Cleaning a clogged nozzle or shaking the can to mix the contents can take just a few minutes. For more complex issues, such as a malfunctioning valve mechanism, it may take longer to diagnose and resolve the problem. Regular maintenance and proper storage can help prevent issues and ensure your spray cans are always ready for use. By following these guidelines, you can address spray can issues efficiently and effectively.

Can I Use This If I Have [Common Issue/Alternative]?

Spray cans are versatile tools that can be used in a variety of situations, even if you encounter common issues or need alternatives. For example, if you’re dealing with a clogged nozzle, simple cleaning techniques can restore functionality. If you prefer a reusable and eco-friendly option, pump sprayers can be a suitable alternative. By understanding the versatility of spray cans and their alternatives, you can adapt to different scenarios with ease and confidence.

Wrapping It All Up

Understanding spray can valve mechanisms can enhance your experience and ensure you get the most out of your spray cans. From proper maintenance and troubleshooting to exploring alternatives, this guide provides the information you need to make informed decisions and achieve the best results. Whether you’re an artist, a DIY enthusiast, or simply someone who appreciates the convenience of spray cans, understanding these mechanisms can help you make the most of your tools and enhance your projects.

What You Should Do Next Based on Your Situation

If you’re experiencing issues with your spray can, start by trying the simple fixes outlined in this guide. If the problem persists, consider consulting a professional for more complex issues. If you’re interested in exploring alternatives, weigh the pros and cons and choose the option that best suits your needs. By understanding your tools and their capabilities, you can make informed decisions and achieve the best results for your projects.

References and Further Reading for Those Who Want to Dive Deeper

For those interested in learning more about spray can valve mechanisms and their applications, consider exploring the following resources:

– Articles and guides on aerosol technology and spray can maintenance

– Online communities and forums where users share tips and experiences

– Manufacturer websites for product-specific information and support

These resources can provide valuable insights and help you deepen your understanding of spray can valve mechanisms and their many uses.

HOW A TOYOTA 4AGE 20VALVE BLACK TOP ENGINE FEELS.

Posts References:

Comprehensive Guide To Aerosol Spray Can Testing – My Framer Site

Control Solutions Inc – The Anatomy of the Aerosol Can – YouTube

Jane Ansems is a highly talented and accomplished spray can artist, known for her intricate, detailed, and thought-provoking works of art. She began her career as a street artist in the early 2010s, quickly gaining recognition for her unique and innovative style.