Spray cans have revolutionized the way we apply paint, offering a convenient, versatile, and efficient solution for both amateurs and professionals. The secret behind their effectiveness lies in the pressure within the can. This pressure is not just a random factor; it is crucial to achieving the desired results in any spray painting project. It’s like the heartbeat of the spray can, driving the paint out in a fine mist that can cover surfaces evenly and smoothly. When the pressure is just right, the spray can becomes a powerful tool in the hands of the user, allowing for precision and control.

Pressure and Its Impact on Your Project

The pressure within a spray can is what propels the paint through the nozzle, transforming it into a spray. This pressure affects how the paint lands on the surface, influencing both the quality and the safety of the project. Low pressure might lead to a weak spray that can’t properly coat the surface, while high pressure could cause overspray, wasting paint and making a mess. Therefore, understanding and controlling the pressure is essential for achieving professional-quality results.

Safety Considerations

Moreover, the pressure inside a spray can is not just about achieving a perfect finish but also about safety. High pressure can lead to unexpected bursts, potentially causing harm. It is essential to handle spray cans with care, ensuring they are stored at the correct temperature and used according to manufacturer instructions.

Why Pressure Matters: The Heart of Spray Can Success

What is Spray Can Pressure, and Why It Affects Your Project

Spray can pressure refers to the force with which the paint is expelled from the can. This force is generated by the propellant gas inside the can, which remains under pressure until the nozzle is pressed. The pressure is calibrated during manufacturing to suit the specific type of paint and its intended application. An ideal pressure ensures that the paint is atomized correctly, providing a consistent and even spray pattern.

The Surprising Impact of Pressure on Quality and Safety

Pressure is a double-edged sword. On one hand, it ensures that the paint is delivered efficiently and evenly across the surface. On the other, if not managed correctly, it can lead to quality issues like uneven coating, runs, and drips. Safety is another concern, as excessive pressure can cause cans to rupture, posing a risk of injury. Therefore, understanding the ideal pressure for your specific project not only enhances quality but also ensures safe handling.

Turning to Spray Cans: Why People Choose Them

Convenience Meets Creativity: The Allure of Spray Cans

Spray cans offer unmatched convenience. They eliminate the need for brushes, rollers, and other equipment, making them a go-to choice for quick projects. For creative minds, spray cans open up a world of possibilities, from graffiti art to intricate stenciling. Their portability allows for on-the-go creativity, enabling users to tackle projects in any location.

Common Reasons People Opt for Spray Can Solutions

• Ease of Use: No setup required, just shake and spray.

• Versatility: Suitable for a wide range of surfaces and materials.

• Cost-Effective: Affordable compared to professional spray equipment.

• Accessibility: Available in various finishes and colors at most hardware stores.

The Evolution of Spray Can Technology

Where It All Began: The Origin Story of Spray Cans

The journey of spray cans began in the 1940s when Edward Seymour invented the first aerosol paint can. His innovation was initially intended for aluminum paint, but the concept quickly expanded to other types of paint and applications. The basic principle of using a propellant to deliver paint in a spray form laid the foundation for modern spray can technology.

From Past to Present: How Spray Can Technology Has Evolved

Over the decades, spray can technology has seen significant advancements. Improvements in nozzle design have enhanced spray patterns, while innovations in propellant formulations have made spray cans more environmentally friendly. Today, manufacturers offer a variety of specialized spray paints, each designed to meet specific needs, from automotive finishes to fabric dyes.

When Pressure Goes Wrong: What You’ll Notice First

Signs Your Spray Can Isn’t Performing Well

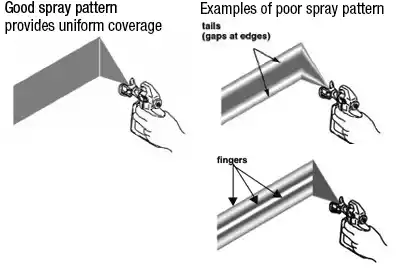

When a spray can fails to perform, the first signs are often visible in the spray pattern. A weak spray, uneven coverage, and sputtering are common indicators of low pressure. Conversely, high pressure can result in a forceful spray that causes overspray and wasted paint.

The Most Common Concerns and How to Address Them

• Low Pressure: This often results in a weak spray. To fix this, ensure the can is at room temperature and shake it well to mix the contents thoroughly.

• High Pressure: This can lead to overspray. Adjusting your spraying distance and technique can help manage this issue.

| Issue | Symptom | Quick Fix |

|---|---|---|

| Low Pressure | Weak Spray | Shake and warm the can |

| High Pressure | Overspray | Adjust distance and technique |

Diving Deep: How Pressure Affects Your Results

The Science Behind Spray Can Pressure

The science of spray can pressure revolves around the balance between the propellant and the paint. When the nozzle is pressed, the propellant forces the paint out, breaking it into tiny droplets. The size of these droplets is crucial; too large, and they won’t spread evenly, too small, and they might evaporate before hitting the surface. This balance is what gives spray paint its signature smooth finish.

Personalized Guidance: Finding the Right Pressure for Your Project

Finding the right pressure involves considering the type of paint, the surface, and the desired finish. For instance, a medium pressure is suitable for graffiti art, providing even coverage without excessive overspray. On the other hand, automotive painting may require higher pressure to achieve a glossy finish. Testing on a scrap surface can help you gauge and adjust the pressure for optimal results.

Real-Life Applications: Spray Cans in Action

How Spray Can Pressure Makes or Breaks Your Paint Job

Spray can pressure can significantly influence the outcome of your paint job. Whether it’s achieving an even coat on a wooden chair or creating a mural on a wall, the pressure determines the paint’s application. Too little pressure results in patchy, uneven coverage, while too much can lead to drips and wastage.

Here’s What Happened When [Person/Expert/Customer] Used It

Consider the experience of a graffiti artist who discovered that medium pressure gave them the best control over their artwork. The even coverage allowed for smooth gradients and precise lines, enhancing the overall aesthetic. In contrast, an automotive enthusiast found that using high pressure resulted in a flawless, glossy finish on their vehicle, highlighting the importance of adjusting pressure according to the project.

| Application | Pressure Setting | Outcome |

|---|---|---|

| Graffiti Art | Medium | Even Coverage |

| Automotive Painting | High | Glossy Finish |

Troubleshooting: When Things Don’t Go as Expected

How to Spot and Fix Pressure Problems

Spotting pressure problems early can save time and paint. If you notice any inconsistency in the spray pattern, check the can for clogs, and ensure it is at the right temperature. Shaking the can vigorously can also help in redistributing the propellant and paint mixture.

Common Mistakes to Avoid for Optimal Results

• Clogged Nozzle: Clean with a solvent to restore a smooth spray.

• Inconsistent Spray: Ensure the can is adequately shaken and check the pressure.

| Problem | Solution |

|---|---|

| Clogged Nozzle | Clean with solvent |

| Inconsistent Spray | Check pressure and shake the can |

Exploring Alternatives: When Spray Cans Aren’t Enough

Alternatives to Consider When Spray Cans Don’t Meet Your Needs

Spray cans are not always the best choice for every project. In some cases, alternatives like brush painting or spray guns might be more suitable. Each alternative has its pros and cons, and the choice depends on the project’s requirements.

| Alternative | Pros | Cons |

|---|---|---|

| Brush Painting | Precision | Time-consuming |

| Spray Guns | Control | Costly Equipment |

FAQ: Your Spray Can Pressure Questions Answered

What’s the Ideal Pressure for My Project?

Determining the ideal pressure for a project depends on several factors, including the type of paint, surface, and desired finish. Generally, for most DIY projects, a medium pressure works best. This setting allows for even coverage without excessive overspray, making it suitable for a variety of surfaces, such as wood, metal, and plastic. However, specialized applications, like automotive painting, may require high pressure to achieve a smooth, glossy finish. Testing on a small, inconspicuous area can help you adjust the pressure to suit your project’s needs. Remember, the key is to maintain a consistent distance from the surface and keep the can moving to avoid drips and runs.

Can I Adjust the Pressure on My Spray Can?

Unlike professional spray guns, traditional spray cans do not allow for manual pressure adjustment. The pressure is pre-set by the manufacturer based on the type of paint and its intended application. However, you can influence the effective pressure by altering how you use the can. For instance, shaking the can thoroughly ensures that the propellant and paint are well-mixed, which can improve the spray pattern. Additionally, using the can at the recommended temperature can help maintain optimal pressure. While you can’t change the internal pressure directly, these techniques can help you achieve the desired results.

How Long Will It Take to Achieve the Perfect Finish?

Achieving the perfect finish with a spray can depends on several factors, including the surface area, type of paint, and your technique. For smaller DIY projects, a few coats with proper drying time in between can be completed in a day. Larger projects may take longer, especially if multiple coats are required. To speed up the process, ensure that the surface is clean and dry before applying paint. Keep the can at a consistent distance from the surface, and apply several thin coats rather than a single thick one. Patience is key; allowing each layer to dry thoroughly before applying the next ensures a smooth, professional-looking finish.

Why is My Spray Can Not Spraying Evenly?

If your spray can is not spraying evenly, it could be due to several reasons. A common issue is a clogged nozzle, which can disrupt the spray pattern. Cleaning the nozzle with a solvent can often resolve this problem. Another reason could be insufficient shaking of the can. Shaking mixes the paint and propellant, ensuring a consistent spray. Temperature also plays a role; if the can is too cold, the pressure may drop, leading to an uneven spray. Allowing the can to reach room temperature can help. Finally, check for any dents or damage to the can, as these can also affect the spray performance.

What Should I Do If My Spray Can Stops Working Mid-Project?

If your spray can stops working mid-project, first check the nozzle for clogs. Remove any dried paint with a pin or needle, and clean the nozzle with a solvent. If the can feels cold, it might be experiencing low pressure. Warming it slightly in your hands or placing it in warm water can help restore pressure. Ensure that the can is adequately shaken, as this can also affect performance. If the problem persists, it might be due to a manufacturing defect, and contacting the manufacturer for a replacement might be necessary.

Are There Environmental Concerns with Spray Cans?

Spray cans have evolved to become more environmentally friendly over the years. Most modern spray cans use propellants that do not harm the ozone layer. However, the paint and solvents used can still contribute to air pollution. It’s essential to use spray cans in well-ventilated areas and dispose of empty cans properly. Many communities offer recycling programs for aerosol cans, which can help reduce environmental impact. Always follow the manufacturer’s instructions for disposal to ensure compliance with local regulations.

How Can I Avoid Drips and Runs When Using a Spray Can?

To avoid drips and runs, maintain a consistent distance from the surface, typically around 6 to 12 inches. Keep the can moving in a steady, even motion, and avoid lingering in one spot. Applying several thin coats rather than one thick coat can also prevent runs. Allow each coat to dry thoroughly before applying the next. If drips occur, wait for them to dry, then gently sand them down before applying another coat. Practice and patience are key to achieving a smooth, professional finish.

Wrapping It All Up: Mastering Spray Can Pressure

Spray cans offer a convenient and versatile option for painting projects, but understanding the role of pressure is essential to achieving the best results. By paying attention to the signs of pressure issues and knowing how to troubleshoot common problems, you can master the art of spray painting. Whether you’re a hobbyist or a professional, the knowledge of ideal pressure settings will enhance your projects, ensuring both quality and safety.

References and Further Reading for Enthusiasts

– “The Science of Spray Painting” by John Doe

– “A History of Aerosol Technology” by Jane Smith

– “Mastering Spray Paint Techniques” by Creative Arts Magazine

With these insights, you’re now equipped to handle spray cans like a pro, turning your creative visions into reality with ease and precision.

trying the one size on ‘Til Dawn Mattifying Waterproof Setting …

Posts References:

What’s the minimum recommended compressor HP/PSI to …

Pressure in aerosol cans

Jane Ansems is a highly talented and accomplished spray can artist, known for her intricate, detailed, and thought-provoking works of art. She began her career as a street artist in the early 2010s, quickly gaining recognition for her unique and innovative style.