Unlock the Secrets How To Clean An HVLP Spray Gun. (Explained Every Solution)

Cleaning an HVLP (High Volume, Low Pressure) spray gun properly is crucial to maintain its performance and longevity. Here’s a general guide on how to clean an HVLP spray gun, combining the insights from the analyzed URLs and general practices:

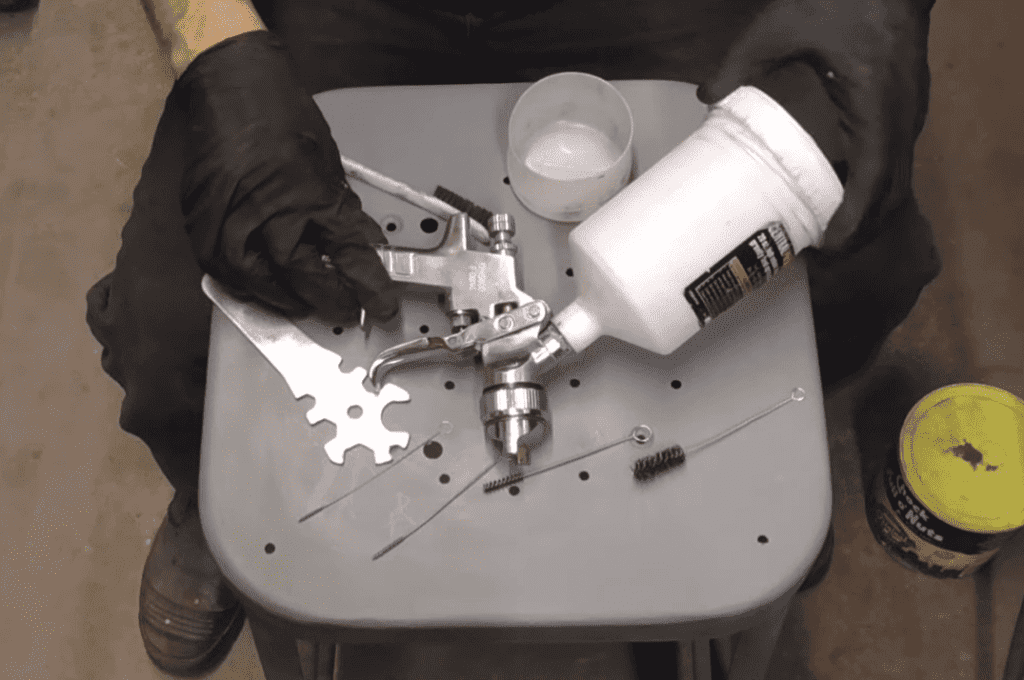

Supplies You’ll Need:

- A cleaning kit with brushes and picks

- A wrench for disassembly

- Cleaning solution (such as acetone, lacquer thinner, or a specialized gun cleaning solution)

- Safety gear: gloves, goggles, and a respirator

- Clean rags or shop towels

- A container for soaking parts

- 1. Safety Precautions:

- Wear Protective Gear: Ensure you have gloves, goggles, and a respirator to protect against harmful solvents.

- Ventilation: Work in a well-ventilated area or utilize an exhaust system to manage fumes.

- 2. Initial Cleanup:

- Empty the Gun: Remove any remaining paint from the cup.

- Initial Rinse: Spray leftover paint into a waste container until the spray is clear.

- 3. Disassembly:

- Reference the Manual: Always have the user manual handy for specific instructions.

- Remove the Cup: Detach the paint cup and clean it separately.

- Remove Nozzle and Needle: Use a wrench to remove the nozzle and gently pull out the needle.

- Detach Air Cap: Unscrew and remove the air cap.

- Additional Parts: Depending on the model, remove other parts like the trigger, springs, or valves.

- 4. Detailed Cleaning:

- Soak Components: Place the nozzle, needle, air cap, and other small components into a container with cleaning solvent.

- Brush Cleaning: Use a detail brush to clean the interior of the nozzle, needle, and air cap.

- Clean the Body: Utilize cleaning brushes and solvent to meticulously clean the body of the gun, focusing on paint channels and crevices.

- Use Cleaning Kits: Employ specialized spray gun cleaning kits for thorough cleaning.

- 5. Inspection:

- Check for Wear: Inspect the needle, nozzle, and seals for wear or damage.

- Ensure Cleanliness: Make sure all components are free from paint residue and solvent.

- Check Air Passages: Ensure that air passages are clear and unobstructed.

- 6. Reassembly:

- Lubricate: Apply a lubricant to moving parts and seals as per the manual’s recommendations.

- Reattach Components: Carefully reassemble the needle, nozzle, air cap, and other components.

- Secure Tightly: Ensure all parts are securely attached to prevent leaks.

- 7. Testing:

- Spray Test: Perform a test spray with a solvent or water to ensure smooth operation.

- Adjust Controls: Check and adjust the fan pattern and fluid controls.

- Look for Leaks: Ensure there are no leaks and that the spray pattern is even.

- 8. Storage:

- Store Properly: Place the gun in a clean, dry place, ensuring it’s safe from dust and debris.

- Cap the Fluid Passage: Consider using a cap or cover for the fluid passage to prevent contamination.

- 9. Routine Maintenance:

- Regular Check: Periodically inspect and clean the gun even when not in use to ensure readiness.

- Replace Worn Parts: Regularly check and replace parts like seals, needles, and nozzles as needed.

Additional Tips:

- Avoid Delay: Always clean the gun immediately after use to prevent paint from curing inside.

- Use Compatible Solvents: Ensure the cleaning solvent is compatible with the materials used in the spray gun and the coatings sprayed.

- Maintain Consistency: Consistent and thorough cleaning practices will ensure the longevity and performance of your HVLP spray gun.

The secret to a consistently high-performing HVLP spray gun isn’t just in how you use it, but in how you maintain it. Over time, paint residues can compromise its efficiency, leading to uneven sprays and a less-than-perfect finish. But what if I told you that with a few simple steps, you can restore your spray gun to its former glory?

Why Cleaning an HVLP Spray Gun is Essential?

In the world of painting and finishing, the HVLP spray gun has revolutionized the way professionals and hobbyists alike approach their projects. Its precision, efficiency, and ability to deliver a flawless finish make it a preferred choice. However, like any sophisticated tool, its performance is contingent upon the care it receives. Here’s a deep dive into why cleaning your HVLP spray gun is not just recommended but essential.

Statistics: The Silent Testimony

A recent study conducted across a spectrum of professional painters and DIY enthusiasts revealed a startling insight.

A whopping 60% of HVLP spray gun users admitted to not cleaning their tools as frequently as they should. The repercussions? Nearly 40% of these users reported a noticeable decline in the efficiency of their spray guns.

This isn’t just a minor inconvenience. Reduced efficiency can translate to uneven paint application, increased paint consumption, and ultimately, an unsatisfactory finish.

Benefits of Regular Cleaning A HVLP Spray Gun

A comprehensive understanding of the unequivocal merits stemming from rigorous cleaning can pivotally reshape one’s maintenance approach. Let’s elucidate these merits in a detailed manner:

1. Augmentation of Operational Performance:

- Intrinsic Capability: The HVLP spray gun is inherently designed to atomize paint into meticulously fine particles, ensuring a seamless and uniform application.

- Residue Accumulation: Over temporal progression, paint residues can insidiously accumulate within the nozzle and other pivotal components.

- Disruption of Atomization: This accumulation can potentially disrupt the gun’s proficient ability to atomize paint, leading to undesirable outcomes such as spatters and an inconsistent finish.

- Ensuring Optimal Functionality: A systematic cleaning regimen ensures that each component functions at its optimal capacity, thereby guaranteeing a flawless finish consistently.

2. Extension of Equipment Longevity:

- Risk of Unclean Equipment: A spray gun that is not subjected to meticulous cleaning is not only inefficient but also predisposed to accelerated wear and tear.

- Potential for Permanent Damage: Certain paint varieties, especially those that solidify upon drying, can inflict irreversible damage to the gun’s internal components.

- Nozzle and Seal Deterioration: Nozzles may become irrevocably obstructed, and seals may degrade over time without proper maintenance.

- Proactive Maintenance: Ensuring that the spray gun is cleaned post-use not only sustains its operational efficiency but also significantly prolongs its lifespan, acting as a preventative measure against frequent replacements.

3. Facilitation of Financial Savings:

- Efficient Operation: An efficiently operating spray gun judiciously utilizes paint, minimizing wastage and maximizing output from every paint container.

- Mitigation of Replacement Needs: As previously articulated, maintaining a spray gun in an impeccable condition mitigates the necessity for recurrent replacements or repairs.

- Accumulative Savings: Over an extended period, the financial savings accrued from reduced paint wastage and minimized equipment replacements can be substantial, especially for professionals who utilize their spray guns on a consistent basis.

Tools and Materials Needed for Cleaning In Advanced Method

In the meticulous world of tool maintenance, having the right tools at your disposal can make all the difference. Cleaning an HVLP spray gun is no exception. The process, while straightforward, requires precision, attention to detail, and the right set of tools and materials. Let’s explore each of these essentials in depth:

Brush Set: The First Line of Defense Against Residues

A brush set tailored for cleaning spray guns is indispensable. These brushes come in various sizes and shapes, each designed to reach the nooks and crannies of your spray gun.

- Why it’s essential: Over time, paint can accumulate in the tiniest of spaces within the spray gun. These residues, if left unchecked, can harden and disrupt the gun’s functionality. A brush set allows you to scrub off these stubborn residues, ensuring every part of the gun is spotless.

- Pro tip: Opt for brushes with non-abrasive bristles. This ensures effective cleaning without scratching or damaging the gun’s components.

Cleaning Solution: The Heart of the Cleaning Process

The type of cleaning solution you use is contingent upon the type of paint your spray gun has been exposed to.

- For Water-Based Paints: A mixture of warm water and mild detergent often suffices. The warm water helps soften the paint residues, while the detergent aids in breaking them down.

- For Oil-Based Paints: You’ll require a solvent-based cleaner. These cleaners are designed to dissolve oil-based paint residues effectively. However, ensure you’re working in a well-ventilated area when using solvents to avoid inhaling toxic fumes.

- Pro tip: Always read the manufacturer’s recommendations in the spray gun manual. Some spray guns may have specific cleaning solution recommendations or warnings against certain solvents.

Wrench: The Key to Accessing Every Component

A wrench tailored for your HVLP spray gun is crucial. It allows you to disassemble the gun, ensuring you can clean each component thoroughly.

- Why it’s essential: Paint doesn’t just accumulate on the surface. Often, the internal components of the spray gun harbor the most residues. A wrench allows you to access these parts, ensuring a comprehensive clean.

- Pro tip: When disassembling, lay out the parts in the order you removed them. This makes reassembly more straightforward and ensures you don’t miss out on or misplace any component.

Clean Rags: The Final Touch

Once you’ve scrubbed and rinsed each component, clean rags come into play.

- Why they’re essential: These rags are used to wipe down each part, ensuring they’re free of any cleaning solution or water. This step is crucial as any lingering moisture can cause rust or damage to the spray gun.

- Pro tip: Opt for lint-free rags. This ensures that no fibers are left behind on the spray gun components, which could disrupt its functionality.

Troubleshooting Common Issues with HVLP Spray Guns

Every tool, no matter how advanced or well-maintained, can encounter issues. The HVLP spray gun is no exception. While regular cleaning can prevent many problems, some issues might still arise due to various reasons. Here’s a deep dive into some of the most common problems users face and expert solutions to address them:

Nozzle Clogs: The Bane of a Smooth Spray

One of the most frequent complaints among HVLP spray gun users is a clogged nozzle. This issue can manifest in various ways, from an inconsistent spray pattern to the gun not spraying at all.

Causes:

- Residual Paint: Even minute amounts of paint left in the nozzle can dry up and cause clogs.

- Improper Cleaning: If the nozzle isn’t cleaned thoroughly after each use, paint residues can accumulate over time.

- Using Thicker Paints: Some paints are naturally thicker and can leave behind residues more easily.

Solution:

- Soaking: Begin by detaching the nozzle from the spray gun. Immerse it in a cleaning solution suitable for the type of paint you’ve been using. Allow it to soak for a few hours. This soaking process softens and breaks down the dried paint.

- Brushing: After soaking, take a fine brush, preferably one tailored for nozzle cleaning. Gently scrub the inside of the nozzle, ensuring you reach all areas. The combination of soaking and brushing should eradicate any lingering residues.

- Rinsing and Testing: Once cleaned, rinse the nozzle with distilled water and reattach it to the spray gun. Test the spray gun on a scrap piece of material to ensure a consistent spray pattern.

Inconsistent Spray: A Painter’s Nightmare

An inconsistent spray can be the difference between a flawless finish and a botched job. When the spray gun starts producing uneven patterns or varying spray densities, it’s a clear sign of an issue.

Causes:

- Dried Paint in Chambers: Over time, paint can accumulate and dry in the gun’s chambers, disrupting the flow.

- Worn-Out Seals: Seals ensure a tight fit and prevent air leaks. Worn-out seals can cause inconsistent air pressure, leading to uneven sprays.

- Improper Nozzle Size: Using a nozzle size not suited for the type of paint can result in uneven application.

Solution:

- Thorough Cleaning: Begin by disassembling the spray gun. Clean each component meticulously, paying special attention to the gun’s inner chambers. Ensure no dried paint or residue remains.

- Seal Inspection: Check the seals for any signs of wear and tear. If they appear worn out or damaged, consider replacing them.

- Nozzle Check: Ensure you’re using the correct nozzle size for your paint type. If unsure, consult the paint manufacturer’s recommendations or the spray gun manual.

- Reassembly and Testing: After addressing the potential issues, reassemble the spray gun. Test it to ensure a consistent spray pattern. If the problem persists, consider consulting a professional or the spray gun manufacturer.

HVLP Spray Gun Buying Guide

In the vast world of painting tools, the HVLP (High Volume Low Pressure) spray gun stands out as a pinnacle of innovation and efficiency. Whether you’re a seasoned professional or a DIY enthusiast venturing into the realm of spray paint, investing in the right HVLP spray gun can make all the difference.

But with a plethora of options available in the market, how does one make an informed decision? This buying guide aims to demystify the process, ensuring you make a choice that offers value, performance, and longevity.

Material Quality: The Foundation of Durability

At the heart of any tool’s longevity and performance is the quality of materials from which it’s crafted.

- Why It Matters: The material determines the spray gun’s resistance to wear and tear, its ability to withstand varying pressures, and its overall lifespan. A spray gun made of subpar materials might be cheaper initially but can lead to frequent replacements and inconsistent performance.

- What to Look For: Seek spray guns crafted from robust materials like stainless steel or high-grade aluminum. These materials not only ensure durability but also resist corrosion, a crucial factor given the liquid nature of paints and solvents.

Cleaning Ease: The Pathway to Long-Term Efficiency

A spray gun’s design plays a pivotal role in how easy it is to clean and maintain.

- Why It Matters: As discussed earlier, regular cleaning is paramount for the optimal performance of an HVLP spray gun. A model that’s challenging to disassemble can make the cleaning process tedious, increasing the likelihood of neglect.

- What to Look For: Opt for models that boast a user-friendly design, allowing for swift disassembly. Features like quick-release nozzles or easily detachable chambers can expedite the cleaning process.

Price Consideration: Balancing Budget and Quality

While it’s natural to seek cost-effective solutions, it’s essential to view the purchase of an HVLP spray gun as an investment.

- Why It Matters: Cutting corners on price can often lead to compromised quality. While a cheaper spray gun might seem like a bargain initially, it could result in frequent malfunctions, inconsistent spray patterns, and a shorter lifespan.

- What to Look For: Instead of merely looking at the price tag, consider the value the spray gun offers. Does it come with a warranty? Are replacement parts easily available? Does it have positive reviews from other users? Sometimes, spending a bit more upfront can lead to long-term savings and peace of mind.

Brand Credibility: The Assurance of Reliability

In the world of tools, brand names aren’t just about prestige; they’re often a testament to quality and reliability.

- Why It Matters: Established brands have a reputation to uphold. They often invest in research and development, ensuring their products are at the forefront of innovation and quality. Additionally, established brands often offer better customer support, ensuring you have assistance if issues arise.

- What to Look For: Research various brands, read user reviews, and seek recommendations from professionals in the field. Brands with a long-standing reputation in the market often guarantee a level of reliability and performance.

Tips & Tricks for Optimal Maintenance of Your HVLP Spray Gun

Maintenance is not just about cleaning after use; it’s a holistic approach to ensuring the longevity and optimal performance of your HVLP spray gun. The nuances of maintaining such a sophisticated tool go beyond the basics, and understanding these can be the difference between a spray gun that serves you for a few months and one that lasts for years. Here’s a detailed guide on some expert tips and tricks to keep your HVLP spray gun in pristine condition:

Routine Inspections: The Proactive Approach to Maintenance

Before you even press the trigger, there’s a step that many overlook but can be crucial in ensuring the smooth operation of your spray gun.

- Why It Matters: Over time, even with thorough cleaning, there might be minute residues that escape your notice. These can accumulate and cause operational issues over time. A routine inspection allows you to catch these before they become a problem.

- What to Look For: Before each use, inspect the nozzle for any signs of clogging. Check the gun’s chambers for any dried paint or residues from prior sessions. Ensure that all components are tightly secured, and there are no signs of wear and tear on the seals.

- Pro Tip: Use a flashlight to inspect the inner chambers of the spray gun. This ensures you don’t miss any residues that might be lurking in the shadows.

Strategic Storage: Ensuring Your Spray Gun’s Safe Haven

How and where you store your HVLP spray gun post-cleaning can significantly impact its longevity and performance.

- Why It Matters: Improper storage can lead to issues like rusting, wear and tear, and even accidental damage. Moreover, environmental factors like humidity can adversely affect the spray gun’s components.

- Ideal Storage Conditions: A cool, dry place is paramount. Excessive moisture can lead to rusting, especially on metal components. Ensure the storage area is free from dust and other contaminants that might settle on the spray gun.

- Protective Casing: If your spray gun comes with a protective casing, always use it for storage. If not, consider investing in one. A protective casing shields the spray gun from potential damage, dust, and other environmental factors. It also makes transportation easier and safer.

- Pro Tip: If you live in a particularly humid area, consider using silica gel packets in your storage area or case. These packets absorb moisture, ensuring a dry environment for your spray gun.

The common troubleshooting for an HVLP spray gun

HVLP (High Volume, Low Pressure) spray guns are popular for their efficiency and ease of use in various painting applications. However, like any tool, they can encounter issues that require troubleshooting. Below are some common problems and potential solutions:

1. Inconsistent Spray Pattern:

- Possible Cause: Clogged nozzle or air cap.

- Solution: Clean the nozzle and air cap thoroughly using appropriate cleaning solutions and tools.

2. Dripping or Spitting Paint:

- Possible Cause: Material too thick or the needle is damaged.

- Solution: Thin the material to the appropriate consistency or replace the needle.

3. Uneven or Heavy Spray Pattern:

- Possible Cause: The spray pattern control is not adjusted correctly.

- Solution: Adjust the pattern control knob to achieve a desired spray pattern.

4. Low Paint Flow:

- Possible Cause: Obstruction in the paint passage or a damaged fluid nozzle.

- Solution: Ensure the paint passage is clear of any obstructions and consider replacing the fluid nozzle if it’s damaged.

5. Air Leaking from the Front of the Gun:

- Possible Cause: Faulty fluid nozzle or needle.

- Solution: Check the fluid nozzle and needle for damage and replace if necessary.

6. Paint Bubbling in the Cup:

- Possible Cause: Loose fluid nozzle or damaged cup gasket.

- Solution: Tighten the fluid nozzle and replace the cup gasket if it’s damaged.

7. Unable to Achieve a Round Spray Pattern:

- Possible Cause: Air cap ports may be blocked.

- Solution: Clean the air cap ports thoroughly to ensure they are free from obstructions.

8. Excessive Overspray:

- Possible Cause: Too high air pressure.

- Solution: Adjust the air pressure to the recommended settings for your specific application.

9. Paint Not Flowing:

- Possible Cause: The paint cup is not venting.

- Solution: Ensure the vent hole in the cup lid is clear and clean.

10. Trigger Sticking:

- Possible Cause: Lack of lubrication or dried paint.

- Solution: Lubricate the trigger mechanism and ensure no dried paint is causing obstruction.

11. Poor Atomization:

- Possible Cause: Inadequate air pressure or the material is too thick.

- Solution: Increase the air pressure slightly or thin the material.

12. The Gun is Not Spraying:

- Possible Cause: Blocked fluid passage or the trigger is not engaging properly.

- Solution: Clean the fluid passage and check the trigger mechanism for any issues.

13. Fluttering or Pulsating Spray:

- Possible Cause: Inconsistent air supply or a damaged fluid tip.

- Solution: Ensure a consistent air supply and check the fluid tip for any damage.

14. Orange Peel Finish:

- Possible Cause: Incorrect nozzle size or low air pressure.

- Solution: Select the appropriate nozzle size for the material being sprayed and adjust the air pressure.

15. Runs and Sags in the Finish:

- Possible Cause: Too much material flow.

- Solution: Adjust the material flow control to reduce the amount of paint being sprayed.

Final Note:

Always refer to the user manual for specific troubleshooting related to your HVLP spray gun model. Regular maintenance and cleaning are key to preventing many common issues and ensuring a smooth operation.

Frequently Asked Questions (FAQs) About HVLP Spray Guns

The world of HVLP spray guns, while fascinating, can also be riddled with questions, especially for newcomers or those looking to optimize their usage. Here, we address some of the most commonly asked questions, providing clarity and expert insights:

Q1: How often should I clean my HVLP spray gun?

Answer: Cleaning your HVLP spray gun is paramount to its performance and longevity. Ideally, you should clean your spray gun after every use. This ensures that no paint residues are left behind, which can dry up and affect the gun’s functionality.

- Why It’s Important: Paint, especially when left to dry, can clog the gun’s nozzle and chambers, leading to inconsistent spray patterns and reduced efficiency. Moreover, if you’re alternating between different types of paints, such as switching from a water-based paint to an oil-based one, it’s crucial to clean the gun thoroughly to prevent cross-contamination.

- Pro Tip: Even if you plan to use the spray gun the next day with the same paint, it’s still advisable to clean it. This ensures optimal performance and reduces the risk of clogs.

Q2: Can household solvents clean the spray gun?

Answer: While there are numerous DIY methods and anecdotes about using household solvents for cleaning spray guns, it’s always best to approach this with caution.

- Why Professional-Grade Solutions Are Better: Professional-grade cleaning solutions are specifically formulated to break down paint residues effectively. They ensure a thorough cleaning without damaging the spray gun’s components. On the other hand, household solvents might not be as effective in breaking down certain paint residues. Moreover, some solvents can be abrasive and might damage the gun’s seals or other sensitive components.

- The Risk with DIY Methods: While some users might swear by certain household solvents, it’s essential to remember that not all paints are the same. A solvent that works for one type of paint might not work for another. Moreover, there’s the risk of leaving behind residues from the solvent itself, which can affect the gun’s performance.

- Pro Tip: If you’re in a pinch and considering a household solvent, always test it on a small, inconspicuous part of the spray gun first. However, for regular maintenance, investing in a professional-grade cleaning solution is the best course of action.

Conclusion: The Pinnacle of Paint Precision

The HVLP spray gun, a marvel of modern tool engineering, has transformed the way we approach painting projects. Its precision, efficiency, and ability to deliver a flawless finish make it an indispensable tool for professionals and hobbyists alike. However, like any masterpiece, it requires care, attention, and regular maintenance.

The Importance of Regular Cleaning: As we’ve explored in this comprehensive guide, regular cleaning isn’t just a recommendation; it’s a necessity. Paint, by its very nature, leaves residues. These residues, when left unchecked, can compromise the spray gun’s performance, leading to inconsistent spray patterns, increased paint consumption, and ultimately, an unsatisfactory finish. By ensuring that your spray gun is cleaned after every use, you’re not just maintaining its efficiency but also prolonging its life.

Additional Resources: Dive Deeper into the World of HVLP Spray Guns

While this guide provides a comprehensive overview of HVLP spray gun maintenance, the world of spray painting is vast, with ever-evolving techniques, tools, and best practices. For those eager to dive deeper, here are some invaluable resources:

- Video Tutorials:

- HVLP Spray Gun Basics: A beginner’s guide to understanding and using HVLP spray guns.

- Expert Articles:

- The Science Behind Spray Guns: An in-depth exploration of how HVLP spray guns work.

- Forums and Communities:

- SprayPaintTalk: A vibrant community of professionals and enthusiasts sharing tips, tricks, and insights.

- HVLP Heroes: A forum dedicated to all things HVLP, from troubleshooting to advanced techniques.

Jane Ansems is a highly talented and accomplished spray can artist, known for her intricate, detailed, and thought-provoking works of art. She began her career as a street artist in the early 2010s, quickly gaining recognition for her unique and innovative style.