For successful roof coating spraying, it is important to use the right equipment. The spray equipment should be able to deliver a consistent and even spray pattern to ensure proper coverage and adhesion of the coating. It is recommended that the minimum pressure for the spray equipment should be at least 2,000 psi.

Roof coating is an important part of maintaining and protecting your roof, but it can be a challenging task to undertake. In this article, we will explore what you need to know about selecting the appropriate airless spray unit for roof coating spraying.

The delivery rate of an airless spray unit is a critical factor in ensuring that your roof coating is applied correctly. The unit should have a delivery rate of at least 1 ½ gallons per minute, and a tip size of 0.030 inches. This combination of delivery rate and tip size will ensure that the coating is applied evenly and effectively. The pressure should also be at least 2,000 psi, which will help to ensure that the coating is applied evenly and effectively.

Larger airless spray units are preferable for roof coating spraying, as they allow for longer hose runs. This can be particularly useful for large jobs where the coating and the airless spray unit can be kept on the ground, with only the hose and gun actually on the roof. This reduces the amount of weight on the roof and makes it easier to maneuver the hose and gun.

Airless spray units are powered by either an electric motor or a gasoline engine. Electric motors may be less complex than gasoline engines, but they can require a very long extension cord, which can cause an appreciable electrical current drop and adversely affect the motor’s efficiency. By contrast, the gasoline airless sprayer is fully self-contained, making it a better choice for most roof coating spraying applications.

As a spray paint artist, I know firsthand the importance of using the right size tip when it comes to painting surfaces. And when it comes to water-based roof paint, the tip size is even more critical.

Why is selecting the right equipment for roof coating spray important?

The roof is one of the most important parts of any building, and protecting it from the elements is crucial to maintaining its integrity. A roof coating can help to extend the life of a roof by providing a protective barrier against UV rays, water, and other weather elements.

However, the success of a roof coating application largely depends on the equipment used. Using the wrong spray equipment can result in an uneven application, causing leaks, cracks, and other damage that can lead to expensive repairs down the road.

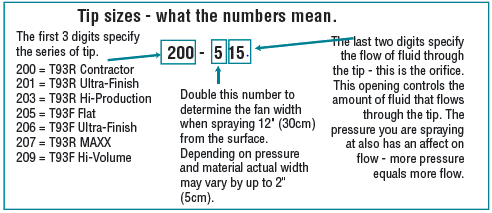

First things first, let’s talk about what tip size means. The tip size refers to the size of the office, or opening, in the spray tip. This opening determines how much paint can flow through the tip, which in turn affects the size of the spray pattern and the amount of paint that’s applied to the surface.

When it comes to water-based roof paint, the recommended tip size is typically between 0.017 and 0.021 inches. This range is considered ideal for this type of paint because it allows for a fine mist to be sprayed, ensuring even coverage and avoiding any overspray.

But why is the right tip size so important? Well, using a tip that’s too small can cause the paint to be applied too thinly, resulting in an uneven finish and potential peeling or flaking over time. On the other hand, using a tip that’s too large can result in too much paint being applied, leading to drips, sags, and wasted paint.

To help you choose the right tip size for your water-based roof paint project, here’s a quick reference chart:

| Paint Type | Tip Size Range |

|---|---|

| Water-Based Roof Paint | 0.017-0.021 in. |

| Latex Paint | 0.015-0.019 in. |

| Oil-Based Paint | 0.019-0.023 in. |

| Stains | 0.011-0.015 in. |

It’s important to note that the tip size you choose also depends on the surface you’re painting. For example, if you’re painting a textured or rough surface, you may want to use a larger tip size to ensure even coverage.

In addition to tip size, there are a few other factors to keep in mind when spraying water-based roof paint. For one, make sure to use the right pressure setting on your spray gun. The ideal pressure range for water-based paint is usually between 1500 and 2000 PSI.

Here is a table that summarizes what Size Tip To Spray Water Based Roof Paint To Use.

| Type of Water-Based Roof Paint | Recommended Tip Size |

|---|---|

| Elastomeric Roof Coating | 0.017 – 0.021 inches |

| Acrylic Roof Coating | 0.015 – 0.019 inches |

| Silicone Roof Coating | 0.019 – 0.021 inches |

It’s essential to note that these tip sizes are just recommendations, and you should always consult the manufacturer’s instructions before starting your project. The manufacturer may have specific recommendations for the type of paint and surface you are working with.

Factors to Consider When Selecting Roof Coating Spray Equipment

- Pressure Requirements

For successful roof coating spraying, the equipment used should be capable of delivering sufficient pressure to ensure adequate coverage and penetration of the coating material. The recommended minimum pressure for roof coatings is at least 2,000 psi. This pressure is necessary to ensure that the coating reaches every part of the roof, including the cracks and crevices, to provide uniform coverage.

- Pump Capacity

The pump capacity is another important factor to consider when selecting roof coating spray equipment. The pump is responsible for moving the coating material from the storage tank to the spray gun. A larger pump capacity will allow for more material to be sprayed in a shorter time, reducing the time and effort required to complete the job. However, it is important to note that a larger pump also requires more power, and this may result in higher operating costs.

- Hose Length

The length of the spray hose is another important factor to consider when selecting roof coating spray equipment. The length of the hose determines the range of the spray gun, and a longer hose provides greater flexibility and allows the operator to access hard-to-reach areas. However, longer hoses may also result in a drop in pressure, which can affect the quality of the coating application.

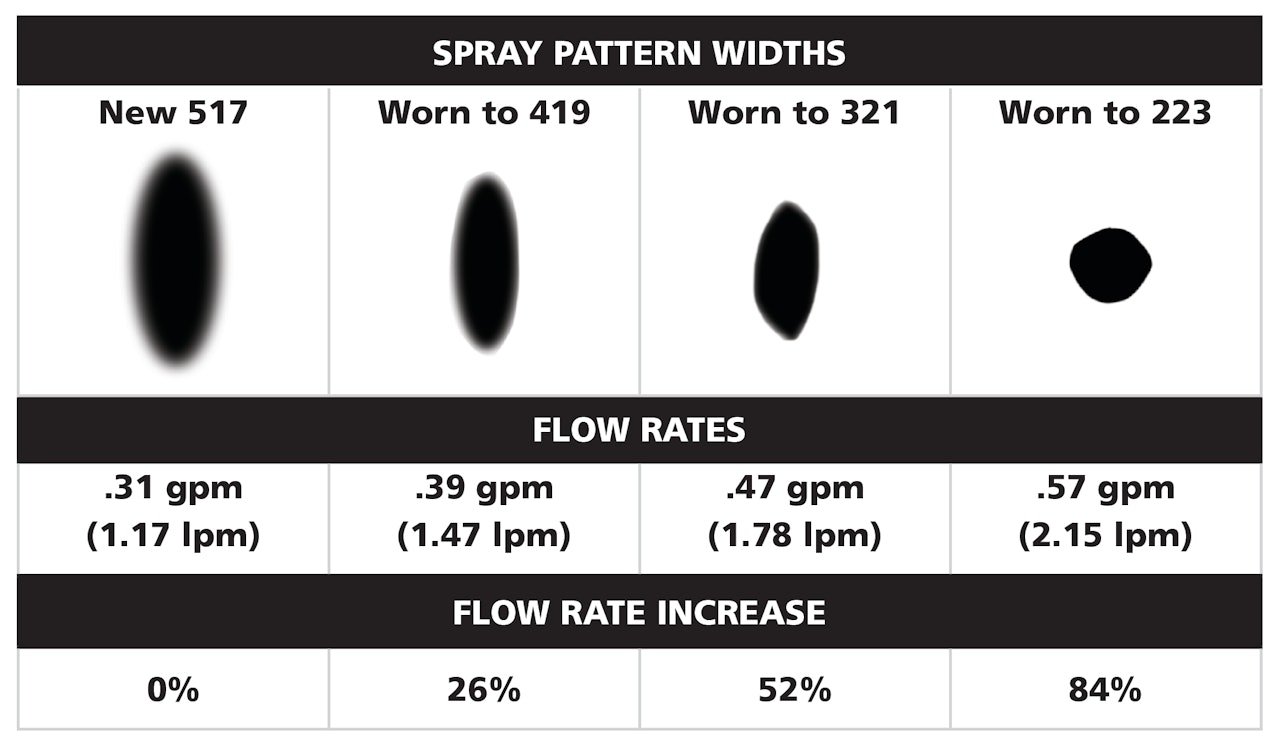

- Nozzle Size

The nozzle size is an essential factor that affects the quality of the coating application. A smaller nozzle size produces a finer spray pattern, resulting in a more even application of the coating material. However, a smaller nozzle size also requires more pressure to achieve the desired flow rate. A larger nozzle size, on the other hand, may result in a thicker coating, but it may also lead to over-spray and waste of material.

- Air Supply

The air supply is another critical factor to consider when selecting roof-coating spray equipment. Airless spray systems use hydraulic pressure to move the coating material, while air-assisted systems use compressed air to atomize the coating material. Air-assisted systems are preferred for roof coatings as they provide a more even application, reduce overspray, and improve transfer efficiency.

What ratio to spray water-based paint?

The ratio of thinning water-based paint for spraying depends on the type of paint and the specific spraying equipment you are using. As a general guideline, you can start with a 10-20% water-to-paint ratio for most water-based paints. However, it is crucial to check the manufacturer’s recommendations as the ideal ratio may vary based on the paint’s formulation.

To achieve the best results:

- Test the paint’s consistency by pouring it through a viscosity cup (such as a Ford or Zahn cup). The paint should flow smoothly without dripping or breaking.

- Gradually add water to the paint while stirring thoroughly. Start with a 10% water-to-paint ratio and adjust as needed.

- Perform a test spray to ensure the paint flows smoothly and consistently through the spray gun.

- Adjust the ratio as needed, adding more water or paint to achieve the desired consistency.

Remember that adding too much water can weaken the paint and adversely affect its adhesion and durability. Always strive for the minimum amount of water necessary to achieve proper playability.

How do you mix water-based paint for spraying?

Mixing water-based paint for spraying requires some attention to detail to achieve the proper consistency and performance. Follow these steps to mix water-based paint for spraying:

- Prepare your workspace: Make sure your workspace is clean, well-ventilated, and free from dust and debris. Gather your materials, including the paint, water, a mixing container, a stir stick or paint mixer attachment for a drill, and a strainer.

- Read the manufacturer’s instructions: Check the paint manufacturer’s recommendations for thinning ratios and any specific guidelines for the paint you’re using.

- Mix the paint: Stir the paint thoroughly to ensure it is well-mixed and free of lumps. If the paint has been sitting for an extended period, it may have separated, so proper mixing is crucial.

- Add water gradually: Begin by adding a small amount of water (typically around 10% of the paint volume) to the paint while stirring continuously. You can use distilled water to minimize any potential contaminants.

- Check the consistency: Assess the paint’s consistency by using a viscosity cup or by observing how it flows off the stir stick. The paint should flow smoothly and consistently, without being too thick or thin.

- Test the spray: Pour the thinned paint through a paint strainer and into the spray gun’s container. This will remove any lumps or impurities that could clog the spray gun. Test the spray on a piece of scrap material to ensure it is applying evenly and smoothly.

- Adjust as needed: If the paint is still too thick or not spraying properly, gradually add more water and mix thoroughly. Remember to add water in small increments to avoid over-thinning the paint, which can compromise its quality and adhesion.

- Clean your equipment: Once you’ve achieved the desired consistency and spray performance, clean your mixing container, stir stick, and any other tools used in the process to maintain their condition and prevent cross-contamination.

Get More Idea From: Easyspraypaint

Always test your paint on a scrap piece of material before spraying your final project to ensure proper adhesion and finish quality.

Is 2x spray paint water based?

2x spray paint typically refers to a type of spray paint that provides twice the coverage or opacity compared to regular spray paint, making it more efficient for various applications. However, the term “2x” does not indicate whether the paint is water-based or solvent-based.

Spray paints can be either water-based (acrylic) or solvent-based (enamel, lacquer, or other formulations). To determine whether a specific 2x spray paint is water-based or not, you should check the product label, the manufacturer’s website, or contact the manufacturer directly. The label should provide information about the type of paint, its base (water or solvent), and instructions for use and clean-up.

Conclusion

Selecting the right roof coating spray equipment is essential for achieving the best results. The pressure requirements, pump capacity, hose length, nozzle size, and air supply are the key factors to consider when choosing the appropriate equipment.

It is important to consult with a professional roofing contractor to ensure that the equipment selected meets the requirements of the specific roofing project. With the right equipment, a high-quality roof coating application can be achieved, resulting in a longer-lasting, more durable roof.

Reference:

Jane Ansems is a highly talented and accomplished spray can artist, known for her intricate, detailed, and thought-provoking works of art. She began her career as a street artist in the early 2010s, quickly gaining recognition for her unique and innovative style.

[…] & Reasoning: This spray paint stands out due to its 2X Ultra Cover Technology, allowing it to cover surfaces twice as much as […]

[…] immediacy. He used a wide range of materials in his paintings, including oil paint, acrylics, and spray paint. His work often features images of skulls, crowns, and masks, as well as text and symbols. […]